Win or lose, the CEE students who travel to Seattle this week to compete in the 2013 Earthquake Engineering Research Institute’s (EERI) Seismic Design Competition have learned one skill that is invaluable to every working engineer: collaboration.

Win or lose, the CEE students who travel to Seattle this week to compete in the 2013 Earthquake Engineering Research Institute’s (EERI) Seismic Design Competition have learned one skill that is invaluable to every working engineer: collaboration.

“We’ve really learned how to size up each other’s skills and make allowances for things we don’t know – like dynamic loading,” says Dan Cannatella, a junior from Florida. “We’ve learned how to work like a team.”

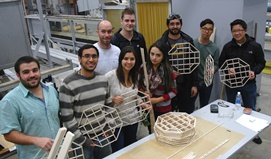

That teamwork has come in handy over the last three months as seven civil engineering students and two architecture students have dedicated themselves to planning, designing and constructing a Georgia Tech Team submission for the national competition, held February 12-15.

Their application must include formal architectural plans and renderings, an analysis of the building’s structural integrity, and a justification for everything from the fire exits to landscaping.

The centerpiece of the Georgia Tech submission is a balsa wood building model, five feet in height, that they constructed and shipped to Seattle on Feb. 9. As per the contest rules, it conforms to all building codes, is appropriate for office and commercial use, provides lots of natural light, and is capable of withstanding three simulated earthquakes.

The centerpiece of the Georgia Tech submission is a balsa wood building model, five feet in height, that they constructed and shipped to Seattle on Feb. 9. As per the contest rules, it conforms to all building codes, is appropriate for office and commercial use, provides lots of natural light, and is capable of withstanding three simulated earthquakes.

“Well, that’s the plan,” said Erika Lopez, a junior CEE student from Bolivia. “The judges will be putting it on a shake table to simulate the earthquakes, and that’s when we find out how well we did.”

The team will also be judged by some fairly stringent aesthetic standards.

“This is supposed to replace the Seattle Space Needle, an iconic structure,” says Cannatella. “So it has to be interesting to look at. It’s got to fit into the Seattle scene.”

The ‘interesting’ part was relatively easy, says Luis Hasbun, a junior CEE student from El Salvador:

“We decided to do an eight-sided building, which is unusual, even for Seattle. And the model we are building goes straight up, but we’ve designed it so that it would twist around like a corkscrew,” he said. “The architectural renderings will show that.”

Using standard CAD software programs, the team came up with plans that spelled out their building process. They also submitted their engineering data to another software program that calculated the building’s ability to handle earthquake-level shaking.

When they ventured beyond these theoretical guidelines, the team faced their greatest challenges.

“We were building it from scratch, so we didn’t have anything to base it on,” said Antonella Ungari, a junior CEE student from Venezuela. “So, all along the way, we were learning new things – about the materials, about the building requirements, everything. We had to make a lot of changes.”

Ungari said her group’s first hurdle was in understanding the actual properties of balsa wood, the contest-mandated building material.

“We thought it would be a lot more stiff, but it was not. So it was easier to cut, but we had a hard time making all of the angles work.”

Adds Gonzalo Marcillo, a junior CEE student from Equador:

“Then we realized that we had to have a one-inch opening [doorway] in some of the interior walls because you have to be able to get out of the building from every room in case of a fire. So we had to cut into the wood before we could put up the walls. That’s a challenge.”

Weight also proved to be a sticking point. The contest rules stipulate that the structure cannot be more than 4.8 pounds, a figure that was quickly exceeded in the Georgia Tech team’s first attempt at construction.

“We could remove a couple of floors to reduce the weight, but that would reduce the overall value of our building,” said Mateo Simone, a junior from Panama. “The upper floors have a greater value than the lower ones, because they have more sunlight, better views. Things like that.”

Under the contest rules, the structure’s value is determined, not only by the cost of building and maintaining it, but by its condition after it has been subjected to the earthquakes. Removing the pricey penthouse views would reduce its weight, he acknowledged, but it would also reduce the overall value from which damages would be subtracted.

“All of these hurdles are a part of the process,” says School Chair Dr. Reginald DesRoches, faculty advisor for the GT student chapter, a member of the EERI and a noted expert on earthquake mitigation.

“We expect our students to stretch themselves in competitions like this one. Not only must they apply very complicated concepts to the design the building, they also have to construct it within financial and aesthetic constraints. Real-world engineering challenges are every bit as demanding.”

A week before they were to arrive in Seattle, team members assembled in the CEE hydrology lab, where their final hours were split between constructing the model and debating last-minute change-orders. Their project mentors, doctoral student Edwin Lim and Facilities Manager Andy Udell, stood by ready to help.

But the discussion was mainly among the team members, all undergraduates.

“Can we use particle board for the base?” asked one.

“No, it has too much glue content,” said another. “Adds to the weight.”

And, as much as the atmosphere was intensively competitive, it lacked tension.

“We are working together,” said Cannatella, eyes riveted to a wall joint that was refusing to sit straight. “We’re going to make this work.”